How HPP High-Pressure Sterilization Machines Are Revolutionizing Food Safety Without Compromising Nu

2025-05-26 15:22:08

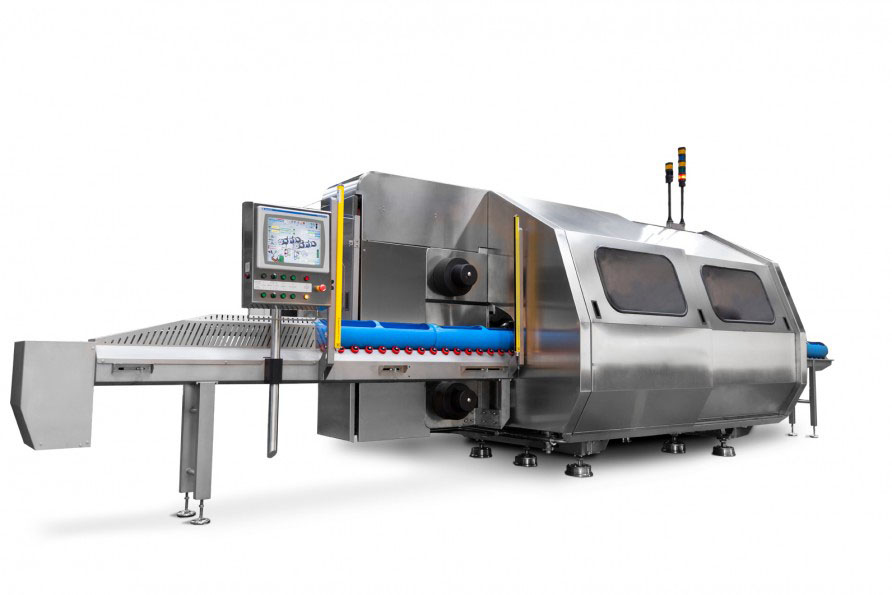

In an era where consumers demand both impeccable food safety and uncompromised nutritional value, the food processing industry faces unprecedented challenges. Traditional sterilization methods like thermal pasteurization or chemical treatments often degrade sensitive nutrients, flavors, and textures. Enter High-Pressure Processing (HPP) sterilization machines—a game-changing technology that uses ultra-high pressure to eliminate pathogens while preserving the integrity of food products.

The Science Behind HPP

HPP machines subject packaged food to extreme hydrostatic pressure (typically between 300–600 MPa), effectively inactivating microorganisms such as bacteria, viruses, and molds. Unlike thermal methods, HPP does not rely on heat, ensuring that vitamins, enzymes, and flavors remain intact. For instance, juices processed via HPP retain 90% of their vitamin C content after 90 days of storage, compared to just 60% for heat-treated counterparts.

Applications Across Industries

From premium juices to ready-to-eat meals, HPP’s versatility shines. Spanish equipment manufacturer Hiperbaric reports that 85% of global HPP installations are in the beverage sector, where brands like Evolution Fresh leverage the technology to extend shelf life without additives. In meat processing, HPP ensures microbial safety in products like sliced ham while maintaining tenderness—a feat impossible with traditional methods. Even delicate items like guacamole and sushi benefit, as HPP prevents browning and spoilage without altering taste.

Economic and Environmental Benefits

While HPP machines require significant upfront investment (ranging from 1millionto5 million per unit), their long-term advantages are compelling. Quintus Technologies’ QIF 600L model, showcased at the 2025 FBIF Food Innovation Expo, processes 4,150 kg of product per cycle, reducing energy costs by 40% compared to thermal systems. Moreover, HPP’s cold-pasteurization capability eliminates the need for preservatives, aligning with the clean-label trend. For every 1,000 tons of HPP-treated juice produced, manufacturers avoid 150 tons of CO2 emissions associated with heat-based preservation.

Case Study: Pet Food Safety

The 2025 pet food recall crisis, linked to Salmonella contamination, accelerated HPP adoption in this sector. By treating raw pet food at 600 MPa, manufacturers like Nature’s Variety achieved a 5-log reduction in pathogens while preserving raw nutrition—a first for the industry. This breakthrough reduced product recalls by 70% and boosted consumer trust, with HPP-treated brands commanding a 25% price premium.

Future Innovations

The next frontier for HPP lies in hybrid systems combining pressure with mild heat or enzymes to tackle heat-resistant spores. Researchers at the University of California, Davis, are piloting a pulsed-HPP system that reduces processing time by 30% while maintaining efficacy. As automation advances, modular HPP units like Hiperbaric’s Bulk 525 will dominate small-batch production, democratizing access to this technology.

HPP sterilization machines are not merely tools—they are catalysts for a paradigm shift in food processing. By harmonizing safety, quality, and sustainability, HPP addresses the trilemma that has long plagued the industry. As consumer awareness grows and regulations tighten, HPP’s role as a cornerstone of modern food manufacturing will only expand.