The impact of low temperature environment on the performance of API 16D fireproof drilling hose and

2025-07-28 10:57:24

In the modern oil and gas extraction industry, drilling operations often face various extreme conditions, especially those carried out in low temperature environments. Under these low temperature conditions, the performance of API 16D fireproof drilling hose may be significantly affected. Therefore, understanding the specific impact of low temperature on these hoses and taking effective countermeasures are important prerequisites for ensuring drilling safety and operational efficiency.

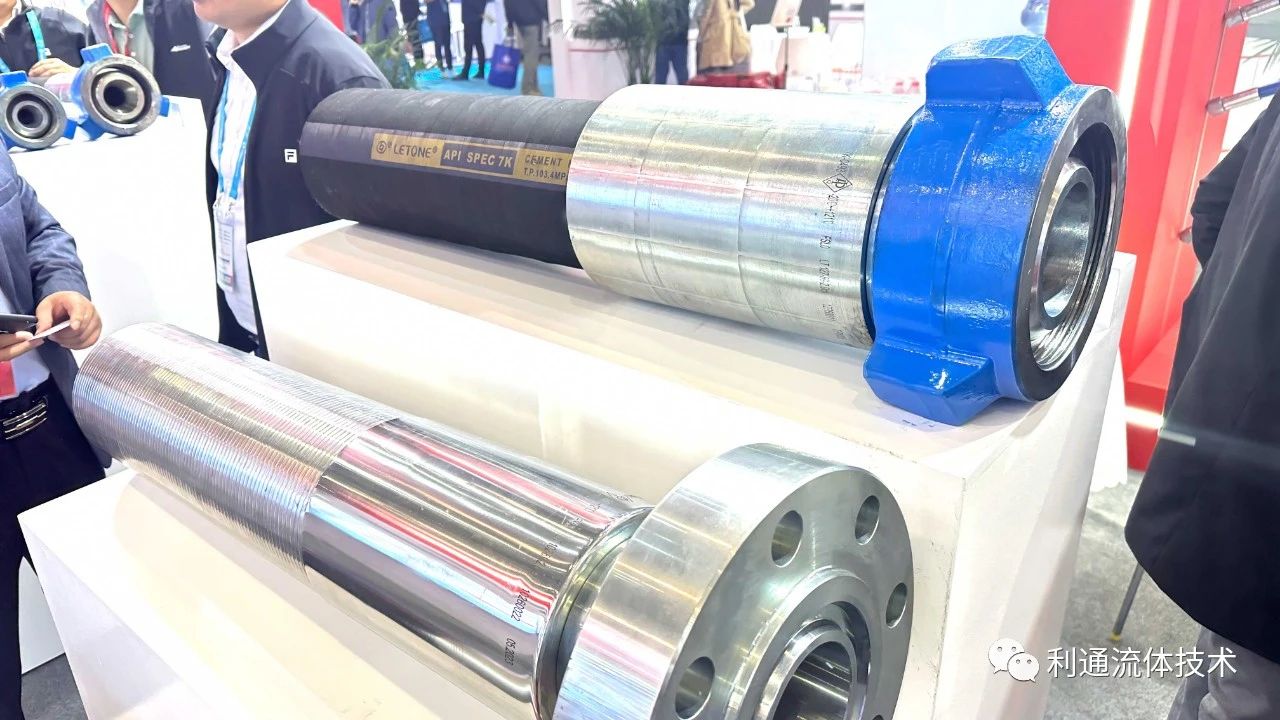

Overview of API 16D fireproof drilling hose

The API 16D standard was developed by the American Petroleum Institute to regulate fireproof hoses used in oil and gas drilling operations. API 16D fireproof hose is mainly used to carry high temperature and high pressure fluids and provide the necessary fire protection to protect the safety of drilling equipment and personnel. This hose is usually made of multiple layers of high-strength materials, including lining, reinforcement layer and outer sheath to ensure its pressure resistance, temperature resistance and corrosion resistance.

Effects of Low Temperature Environment on API 16D Fireproof Drilling Hose

In low temperature environment, drastic temperature changes and cold climate conditions have many effects on API 16D fireproof drilling hose. Here are some of the main influencing factors:

1. Increased material brittleness: Many high-performance materials will reduce their toughness at low temperatures, resulting in increased brittleness. This means that the hose may crack or break when subjected to external impact or bending. In addition, this phenomenon may also cause the sealing performance of the connection to decrease, increasing the risk of leakage.

2. Fluid viscosity changes: Under low temperature conditions, the viscosity of the drilling fluid usually increases. This means that the resistance to the flow of the fluid inside the hose increases, which may lead to a decrease in flow. To overcome this situation, operators may need to increase the pumping pressure, which further increases the load on the hose, affecting its performance and life.

3. Hose shrinkage: In low temperature environments, the material of the hose may shrink thermally, resulting in changes in the length and diameter of the hose. This change may cause loose connections with other equipment or even leaks at the connection.

4. Reduced fatigue resistance: Under low temperature conditions, the fatigue resistance of the hose may decrease, especially when it is frequently bent or twisted. This situation may cause cracks or other damage to the hose after a period of use.

5. Reduced fire resistance: Although the fire-resistant hose under the API 16D standard has good fire resistance, the low temperature environment may cause the ignition point or melting point of some materials to change, thereby weakening its original fire resistance.

Countermeasures and countermeasures

In order to cope with the impact of low temperature environment on the performance of API 16D fire-resistant drilling hose, the relevant industry needs to take a variety of effective countermeasures:

1. Select the right material: In a low temperature environment, it is crucial to select materials with good low temperature performance. The use of special rubber or synthetic materials can improve the toughness and durability of the hose at low temperatures. These materials can still maintain good mechanical properties and sealing in extremely cold conditions.

2. Strengthen fluid management: In a low temperature environment, the management of drilling fluid is particularly important. Operators should monitor the temperature and viscosity of the fluid, and if necessary, add appropriate additives to reduce the viscosity of the fluid to ensure that the fluid is unobstructed during drilling.

3. Use of heating devices: In low-temperature operations, insulation or heating facilities can be considered. Heating devices can protect hoses and their connecting parts to avoid material shrinkage and brittleness caused by low temperatures. In addition, appropriate insulation measures can also help maintain drilling fluid temperature and reduce the impact of viscosity changes.

4. Regular inspection and maintenance: Under low-temperature conditions, regular inspection and maintenance of API 16D fire-resistant drilling hoses are very necessary. By monitoring the appearance of the hose, the sealing of the connecting parts and the circulation of the internal fluid, potential problems can be discovered in time, and corresponding measures can be taken to repair and replace them.

5. Develop emergency plans: In low-temperature environments, developing detailed emergency plans can minimize the impact of emergencies. For example, preparing corresponding spare parts and treatment plans in advance for hose ruptures, leaks, etc. can ensure rapid response when problems occur and reduce the time of operational downtime.

In summary, the low-temperature environment has a significant impact on the performance of API 16D fire-resistant drilling hoses, resulting in potential safety hazards and reduced work efficiency. Therefore, it is crucial to understand these influencing factors and take effective preventive and countermeasure measures. By selecting appropriate materials, strengthening fluid management, using heating devices, regular inspection and maintenance, and formulating emergency plans, the industry can effectively reduce the risks brought by low temperatures and ensure the safety and efficiency of drilling operations.