Hydraulic Brake Hoses: The Unsung Heroes of Heavy-Truck Stopping Power

2026-01-27 09:46:37

Why Hydraulic Brake Hoses Are Essential for Heavy-Truck Safety

Heavy-duty trucks carrying 40-ton loads require braking systems that respond instantly and consistently. Hydraulic brake hoses play a silent but critical role in this by ensuring fluid flows smoothly under pressure, even when the truck is braking hard on steep grades or navigating sharp turns. A single compromised hose can lead to uneven braking, increased stopping distances, or complete brake failure—posing catastrophic risks to drivers, cargo, and other road users. Standards like FMVSS 106 and ISO 4753 mandate rigorous testing for burst strength, impulse cycles, and environmental resistance, ensuring hoses meet the demands of commercial trucking. For fleet managers, choosing hoses that comply with these standards is a proactive step toward creating safer roads and avoiding costly liabilities.

Innovations Driving Performance in Heavy-Duty Applications

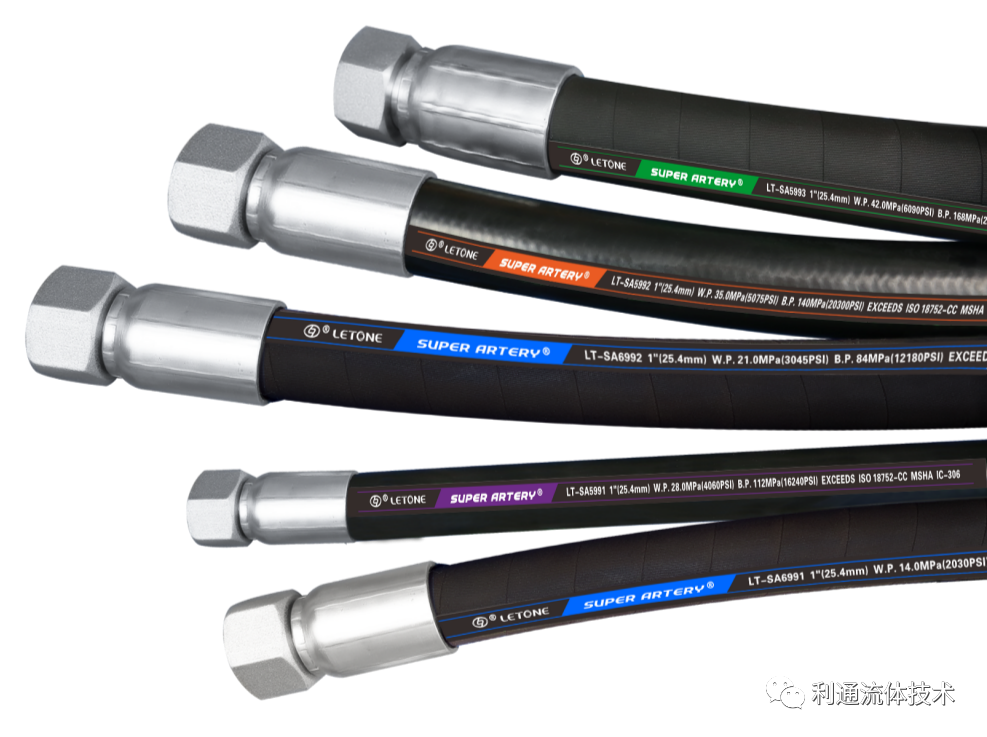

Modern hydraulic brake hoses incorporate advanced materials and designs to meet the rigors of heavy-truck operations. For example, hoses with thermoplastic inner tubes resist high-temperature brake fluids, while steel wire-reinforced layers handle extreme pressures without compromising flexibility. Some feature anti-static coatings to prevent spark risks near fuel tanks, while others use compact spiral wraps for tighter bending radii in crowded engine bays. Color-coded layers or embossed labels simplify identification, reducing installation errors and speeding up maintenance. These innovations minimize downtime and enhance braking precision during critical tasks like emergency stops or downhill descent control.

The Hidden Dangers of Neglecting Brake Hose Maintenance

Cutting corners on brake hose quality or upkeep can have dire consequences for heavy-duty trucks. A leaking hose might introduce air into the system, causing spongy brakes or reduced pedal feel, while a burst hose could disable braking entirely. Even minor wear, like cracks or frayed covers, can escalate under pressure, leading to sudden failures during high-speed maneuvers or heavy loads. Regular inspections, pressure testing, and replacement schedules are essential to mitigate these risks. Training drivers and mechanics to spot early warning signs—such as bulges, leaks, or unusual noises—can prevent accidents before they happen, protecting both personnel and equipment.

Proactive Strategies for Maximizing Brake Hose Lifespan

To ensure hydraulic brake hoses perform reliably, fleet teams should adopt a proactive maintenance approach. Start by selecting hoses rated for your truck’s specific pressure and temperature requirements. During installation, avoid sharp bends or twists that could stress the reinforcement layers. Use compatible fittings and clamps to prevent leaks, and route hoses away from heat sources or moving parts. Store spare hoses horizontally in a clean, dry area to avoid deformation. Finally, implement a digital tracking system to monitor usage hours and schedule replacements before hoses reach their end-of-life. By treating brake hoses as critical safety components, fleet operators safeguard their drivers and maintain operational continuity.